What are the different Types of Master data in SAP MM?

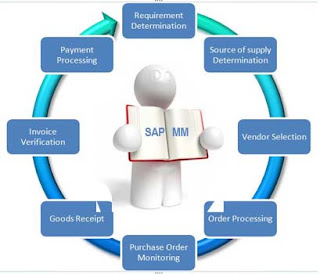

The Master data in SAP is used to be base data that can store all the required inform about the transaction. If someone producing, transferring stock, selling, purchasing, doing physical inventory it necessary to maintain some data that includes material master data,vendor master data and purchasing master data.The below post we are going to discuss the information of different types of master data in sap mm.

Material master data, The basic details on materials an enterprise procures externally or produces in-house. The unit of measure and the description of a material are examples of the data stored in a material master record. Other SAP Logistics components also access the material data.

The material master database (often referred to simply as the “material master“, and comprising all the individual material master records stored in the system) contains descriptions of all materials that an enterprise procures, produces, and keeps in stock. It is the central repository of information on materials (such as inventory levels) for the enterprise.

The integration of all material data in a single materials database eliminates the problem of data redundancy and permits the data to be used not only by Purchasing, but by other applications (such as Inventory Management, Materials Planning and Control, Invoice Verification, and so on).

The Master data in SAP is used to be base data that can store all the required inform about the transaction. If someone producing, transferring stock, selling, purchasing, doing physical inventory it necessary to maintain some data that includes material master data,vendor master data and purchasing master data.The below post we are going to discuss the information of different types of master data in sap mm.

Material master data, The basic details on materials an enterprise procures externally or produces in-house. The unit of measure and the description of a material are examples of the data stored in a material master record. Other SAP Logistics components also access the material data.

The material master database (often referred to simply as the “material master“, and comprising all the individual material master records stored in the system) contains descriptions of all materials that an enterprise procures, produces, and keeps in stock. It is the central repository of information on materials (such as inventory levels) for the enterprise.

The integration of all material data in a single materials database eliminates the problem of data redundancy and permits the data to be used not only by Purchasing, but by other applications (such as Inventory Management, Materials Planning and Control, Invoice Verification, and so on).

Vendor master data called as Information about external suppliers. The vendor’s name and, the currency the vendor uses, and the vendor number (stored in the SAP system as an account number) are typical vendor data.

The vendor master database contains information about the vendors that supply an enterprise. It consists of a large number of individual vendor master records, each containing the relevant vendor’s name and address as well as data such as:

- The currency used for ordering from the vendor

- Terms of payment

- Names of important contact persons (sales staff)

In Accounting, the vendor represents an account payable, the vendor master record also contains accounting information, such as the relevant control account (reconciliation account) in the general book keeping system.

Therefore, the vendor master record is maintained by both Accounting and Purchasing.

Purchasing master data, such as the following:

Purchasing info record establishes the link between material and vendor, thus facilitating the process of selecting quotations. For example, the info record gives the unit of measure used for ordering from the vendor, and indicates vendor price changes affecting the material over a period of time.

Source list, The source list specifies the possible sources of supply for a material. It shows the time period during which a material may be ordered from a given vendor.

Quota arrangement, specifies which portion of the total requirement of a material over a certain period is to be assigned to particular vendors on the basis of quotas.

This section provides an overview of materials planning and control and shows how the latter affects the purchasing activities in the SAP system.

Therefore, the vendor master record is maintained by both Accounting and Purchasing.

Purchasing master data, such as the following:

Purchasing info record establishes the link between material and vendor, thus facilitating the process of selecting quotations. For example, the info record gives the unit of measure used for ordering from the vendor, and indicates vendor price changes affecting the material over a period of time.

Source list, The source list specifies the possible sources of supply for a material. It shows the time period during which a material may be ordered from a given vendor.

Quota arrangement, specifies which portion of the total requirement of a material over a certain period is to be assigned to particular vendors on the basis of quotas.

This section provides an overview of materials planning and control and shows how the latter affects the purchasing activities in the SAP system.